Product introduction:

The glove integrity tester is a special instrument used to test the integrity of isolator, RABS system detachable sheath for a sleeve, gloves or integrated gloves. Includes an operator-friendly control panel, a control system, and a test port that can be paired with an isolator operation port. The glove integrity tester works in positive pressure mode. The test result is displayed as a pressure drop per unit time. The operator determines the integrity of the test gloves based on the reference values provided by the manufacturer.

Working Principle:

The working principle of glove integrity test: Use the glove-specific inflation system to fill air, and the charged gas is charged into the glove through the electronic valve. When the pressure inside the glove exceeds the pressure set by the glove, the glove-specific inflation system stops working and the system enters holding pressure test phase: If the holding time of the positive product is exceeded, and the current pressure is greater than the set value of the positive product pressure, a voice-activated reminder sounds and the detection is positive; the holding time of the positive product and the defective product is exceeded and the pre-job pressure is less than the positive product pressure If the pressure is higher than the set value of the defective product, the sound-activated reminder sounds 2 beeps and detected as a good product; if the current pressure is less than the defective product’s pressure set value, the defective product’s sound-controlled reminder sounds 3 beeps and it is detected as a defective product.

Features:

Convenient structure design, easy to use;

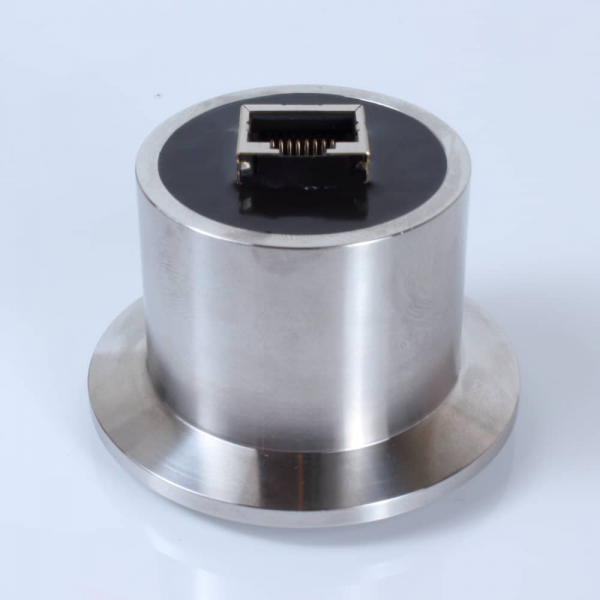

All stainless steel case, easy to clean, suitable for use in clean area;

Tilt control panel; easy to observe and operate;

No external test gas is required, ordinary gas can be used;

Anticorrosive Teflon glove fixing device;

8-10 inch gloves can be tested, saving cost and simple replacement;

Provide real-time printing of test results for easy record keeping;

Can be used by programmable control (PLC) and touch screen for control, with friendly human-computer interaction interface;

The sleeve can be tested for leaks before or after the isolator is used;

Developed according to ISO14644-7 Standard II.

Reviews

There are no reviews yet.