With the increasing market position of new energy industry, lithium battery has become the focus of attention. The utility model provides a lithium automation production line, which can realize the full-automatic code scanning, liquid injection, weighing, liquid replenishing and sealing operation in the super purification glove box, realize the high-efficiency and completely unmanned automation production, greatly save the labor cost, greatly improve the production capacity, product quality and yield, and maximize the benefits for customers. The production line is a revolution of lithium battery / super capacitor production.

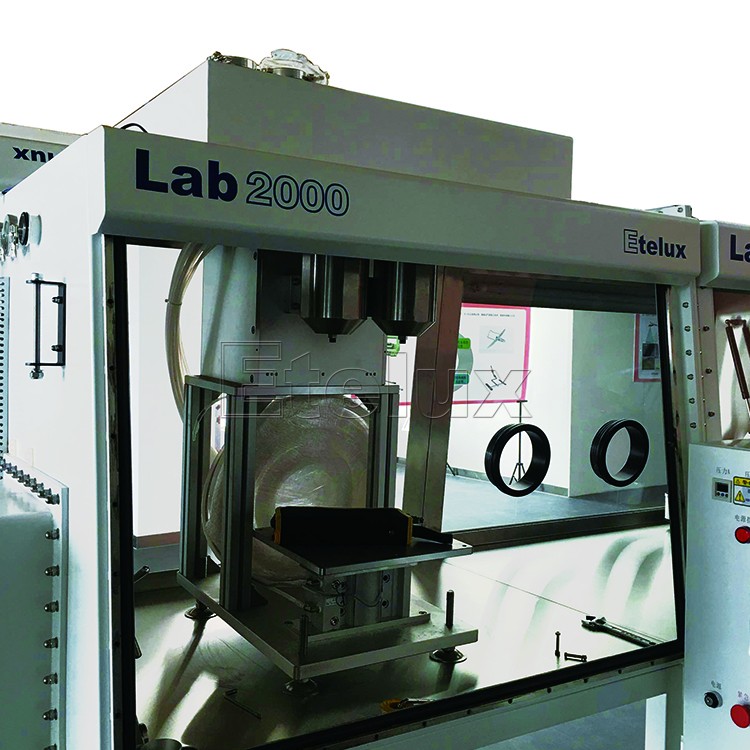

The integrated lithium battery production line consists of oven, cooling glove box, liquid injection glove box, buffer glove box, extrusion (standing) vacuum chamber, sealing glove box and discharge vacuum chamber.

Advantages of lithium battery automatic production line: seamless connection between oven and glove box, continuous production, fast cooling speed, no water and no oxygen operation environment, automatic transmission and other functions. It can realize automatic production of battery, greatly improve production efficiency and save human capital.