With the gradual breakthrough of key technologies of lithium-ion batteries, the application fields of lithium-ion batteries have developed from portable electronic products to the fields of electric vehicles and energy storage grids. At the same time, people are more concerned about the safety of lithium-ion batteries. Therefore, while improving the energy density and power density of lithium-ion batteries, safety issues have become one of the key issues to be solved.

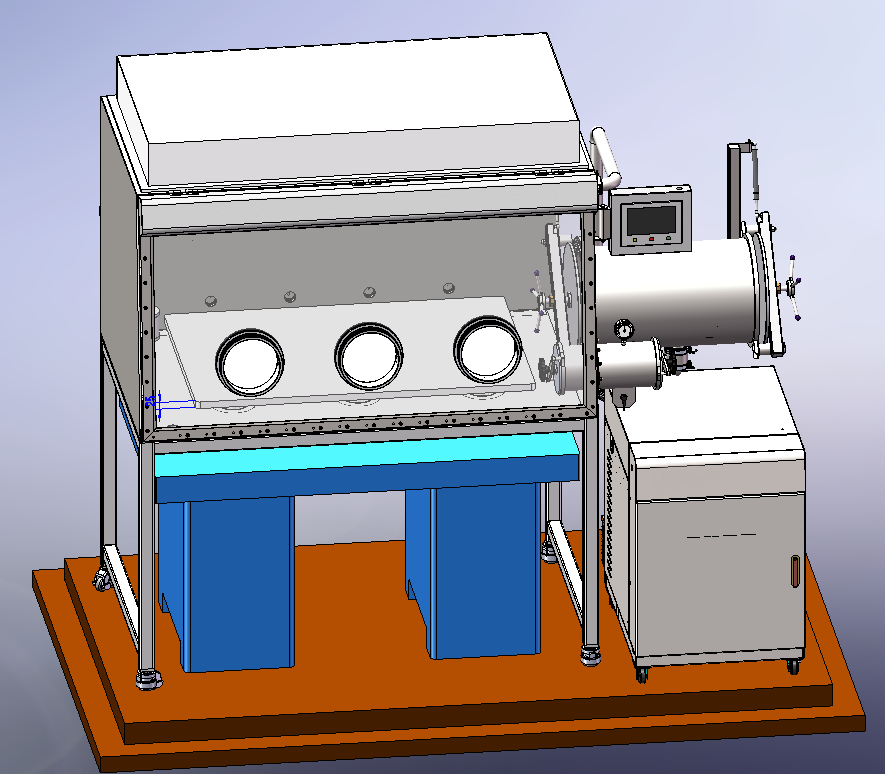

An automatic production line for lithium batteries is provided. The integrated production line consists of an oven, a cooling glove box, a liquid injection glove box, a buffer glove box, a squeeze (static) vacuum box, a sealed glove box, and a discharge vacuum box. The oven and the glove box are seamlessly connected to achieve continuous production. After baking, the battery core is always kept in a water-free and oxygen-free glove box environment. The entire production line includes a cooling glove box, which has a fast cooling speed and low cost, ensuring that the battery cells are baked from filling to filling, and the sealing process is operated in a controlled anhydrous and oxygen-free environment, providing the most solid protection for the quality of the battery.

Lithium battery automated production line can realize full automatic code scanning-injection-weighing-rehydration-sealing operation in the super purification glove box, realizing efficient and completely unmanned automated production, greatly saving labor costs, greatly improving productivity and product quality and finished products Rate to maximize customer benefits.