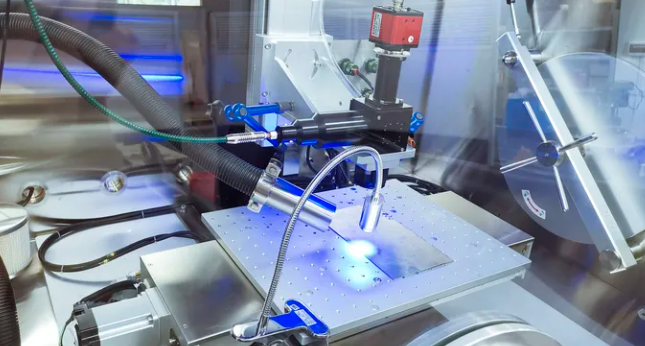

Laser welding is a high-precision welding technique that utilizes the high energy density of a laser beam to melt and join materials. In the laser welding process, a laser generates a high-intensity, focused laser beam and focuses it on the area to be welded.

When the laser beam hits the surface of the material, the energy of the beam is absorbed and converted into heat. This causes the material to heat up quickly and reach the melting point, creating a molten pool. By controlling the power, duration and focusing position of the laser beam, the shape and size of the pool can be precisely controlled.

Once the pool is formed, the materials to be welded can be placed together, utilizing the heat from the pool to fuse them together. When the molten pool cools and solidifies, the welding is complete. Laser welding can be used to weld metals, plastics and other materials with high efficiency, high precision and no contact.

Laser welding is widely used in manufacturing, especially in the automotive, aerospace, electronics and optical industries. It can be used for applications such as welding parts, assembling devices, sealing packages, and cutting or punching materials. Laser welding is often regarded as a high-quality, efficient welding method because it offers a smaller heat-affected area and less distortion.

Combining laser welding with a glove box can fulfill the need for high precision welding in a controlled environment. Gloveboxes are hermetically sealed, closed systems used for handling sensitive materials or for experiments and operations in specialized environments. By integrating laser welding equipment and associated safety measures inside the glove box, the following goals can be achieved:

Controlled environment: The glove box provides a controlled environment that prevents external contaminants from entering the welding area. This is important for welding applications that require a high-purity or dust-free environment.

Increased Safety: Laser welding often requires protection of the operator from the effects of laser radiation. The airtight construction of the glove box can provide an additional layer of safety, ensuring that the operator is kept away from the laser radiation, reducing the potential risk of laser radiation to the environment and the human body.

Controlled Atmosphere: Some welding applications require specific atmosphere conditions such as inert gas or atmosphere control. Gloveboxes can provide atmosphere control to ensure that the atmosphere during the welding process is as required.

Protecting sensitive materials: Gloveboxes can maintain low or controlled humidity to prevent moisture damage to sensitive materials. This is important for applications that require welding in a dry environment.

Precise operation: The interior of the glove box provides a stable working platform that reduces the effects of external vibrations or disturbances on the welding process. This helps to achieve high precision welding operations and quality control.