As we all know, there are some experiments in scientific experiments that are dangerous, such as flammable and explosive chemical experiments,

biological experiments that produce bacteria,

and all experiments that require a clean and safe environment.

In chemistry, physics, biology, medicine, electronics, nuclear energy and other fields of various industries, often need to operate in special environments, such as chemical reactions, inert gas protection under the anhydrous, anaerobic operation; in biological and medical experiments, aseptic, dust-free and other clean environments, operation; in the anaerobic, inert gas protection or the nuclear screen open to the conditions of the manual operation and so on.

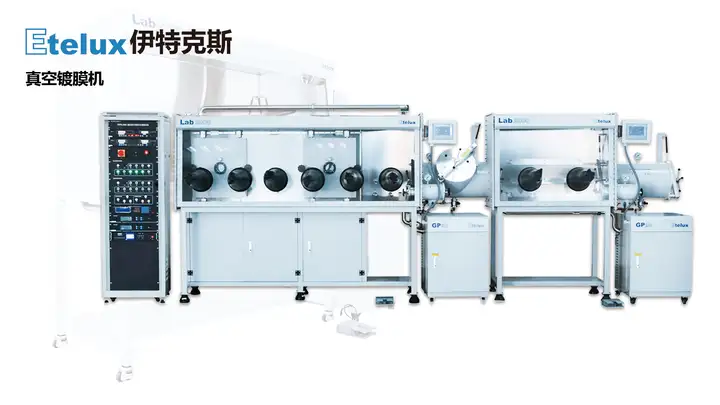

In these cases, people usually use the operation box, also known as the glove box to create these special environments.BUT now on the market part of the glove box, including plastic glove bags and plexiglass glove box: plastic glove bags are low-cost, easy to change the air, but due to the lack of a fixed shape, the operation is not convenient. Plexiglas glove box is usually made of multiple pieces of Plexiglas bonded rectangular, low strength, poor airtight, can not be decompression pumping gas replacement operation. The structure and operability of the existing glove box still cannot meet the needs of industrialized production, and is in urgent need of improvement. Etex provides a nitrogen protection glove box with reasonable structure and strong operability. The beneficial effect is that because the box and the carrier are stainless steel structure, the strength of the whole product increases, the structure is more reasonable; box on the front side panel of a variety of instrument panels can be implemented from outside the box to know the parameters of the box, the operability is greatly enhanced. Of course, not only nitrogen, argon and other inert gases throughout the glove box water, oxygen <0.1ppm leakage rate <0.001vol%/h and a set of vacuum purification system has created a safe experimental environment.

1, regardless of whether to open the glove box door or outside the door must ensure that the door on both sides of the air pressure is basically balanced or can not be opened, or the phenomenon of “gas explosion”. Similarly, the box in the body of the pumping and inflation, must also ensure that the three-way valve is open (that is, to ensure that the glove inside and outside the air pressure is equal), otherwise, the glove will expand and burst.

2, such as the box leakage, should first check whether the transition chamber door is closed and whether the glove mouth is broken. If there is still air leakage, please check the vacuum gauge seat, valve and two doors on the “O” ring and vacuum rubber. The “O” ring on the door of the transition chamber and the door of the glove port should be replaced regularly (according to the user’s frequency of use).

3, the system pumping, please slowly open the valve, and always pay attention to the changes in the glove, such as expansion, should slow down the pumping speed, such as still can not solve the problem, should stop pumping, such as the glove burst, check whether the three-way valve is open.