With the progress and development of society, batteries play an increasingly important role. On the one hand, the improvement of people’s living standards has made electronic products such as mobile phones and notebooks a necessity for most people. With the rapid development of these electronic products, the requirements for batteries have become higher and higher. On the other hand, the energy crisis and environmental pollution have become increasingly prominent, and the development of renewable energy and electric vehicles has become an irresistible trend. In the efficient use of renewable energy such as wind energy, solar energy, etc., energy storage and transmission issues need to be addressed, and the development of electric vehicles also needs to address energy storage and conversion issues. Lithium-ion batteries have the advantages of high energy density, low self-discharge rate, long cycle life, and memory effect. They are widely used in various types of portable electronic devices. With the continued innovation of batteries, lithium-ion batteries are moving towards the field of electric vehicles. .

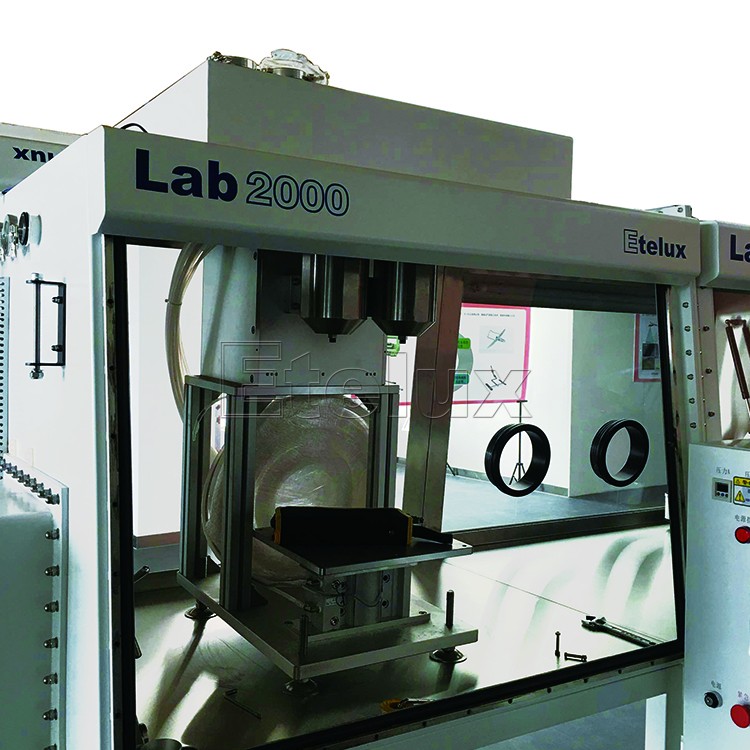

Provide a lithium battery automated production line. The lithium battery automated production line can realize fully automatic code scanning-injection-weighing-rehydration-sealing operation in the super purification glove box, realizing efficient and completely unmanned automated production, greatly saving labor costs, and greatly Improve productivity and product quality and yield to maximize customer benefits.

Functional description of automatic production line for lithium battery: battery raw material package enters glove box from the feed bin; battery raw material package is automatically scanned and weighed, and the weighed battery raw material package is automatically placed in the material conveying device; the conveying device automatically enters the liquid injection cylinder Fill the liquid; the batteries after the filling are respectively placed in the stationary cylinders 1, 2, and 3 for standing; the batteries after the standing are placed in the sealing cylinders to evacuate and seal; the sealed batteries will be automatically weighed twice, Unqualified products will enter the recycling transition bin on the left for processing; qualified batteries will be automatically sent to the discharge bin.