Glove Box with Gas Purification System

Three port Glove box with gas purification system for providing moisture and oxygen free inert environment (i.e.

Atomic Force Microscopy in N2 Atmosphere Glove Box

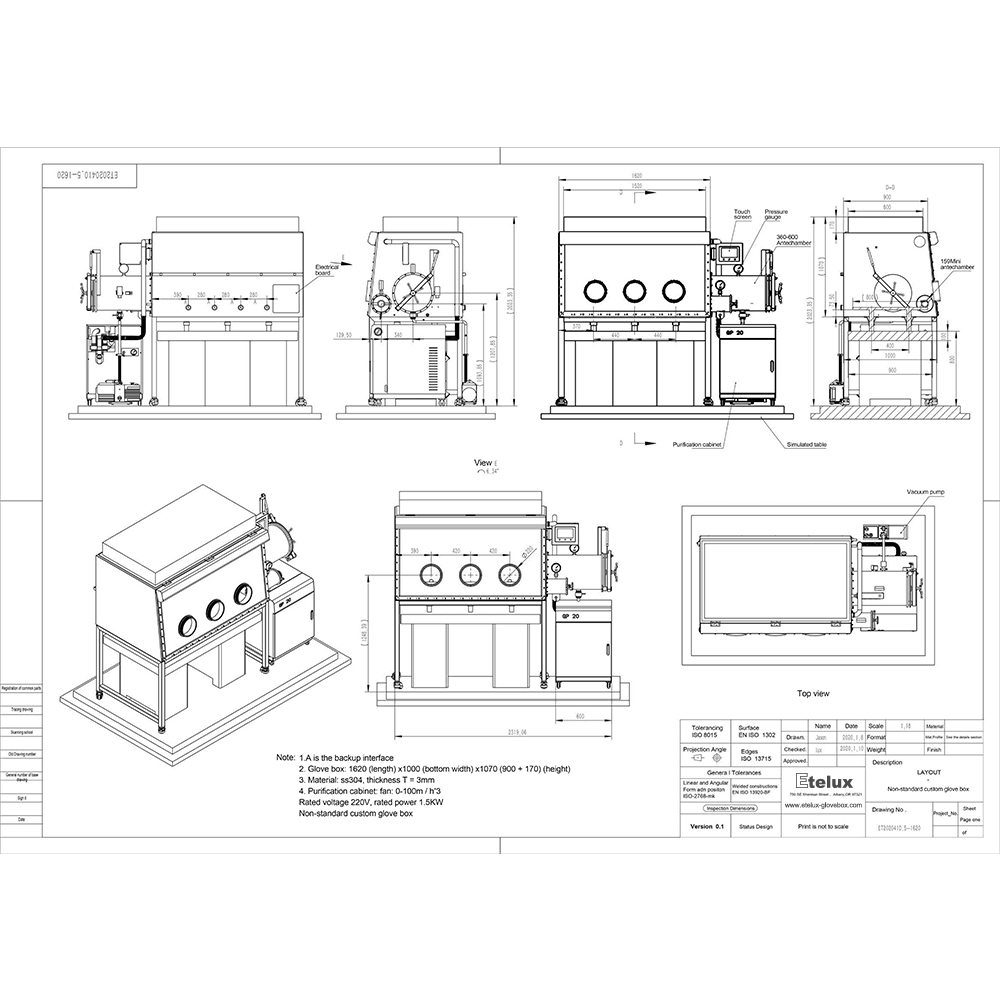

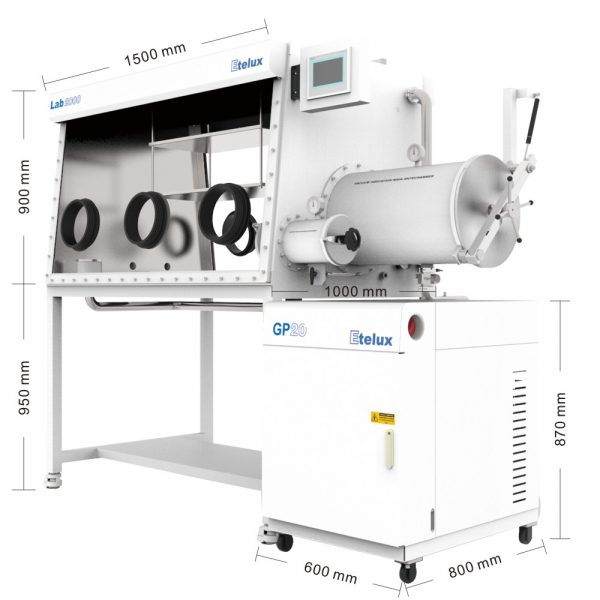

Internal dimension: Length- ~1500 mm, Height- ~900 mm, Depth -~725mm.

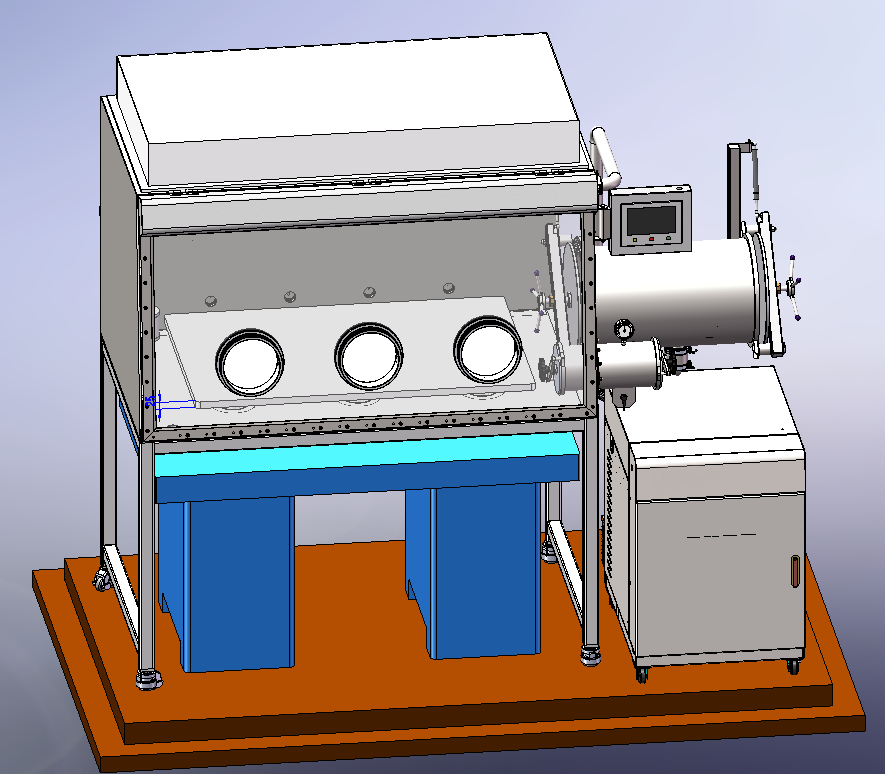

Design Type: Modular double type having Big and Small Antechamber on Right Hand side of Glove Box and build with leak tightness of Class I to standard ISO 10648-2 (Oxygen method)

Modular glove box with dismountable side panels; with secure side panels with appropriate butyl sealings or similar (no silicon glued panels).

The glove box must have possibility to dismount a side panel to connect a second module of glove box for expandable working area. The glove box must have adaptations and adequate blanked piping’s for connection of the purification unit to the 2nd additional glove box module.

Integrated with Gas Purification System and complete piping made of SS 304

Working Environment: Nitrogen or Argon. Material of construction: SS 304

Leakage rate –-5 mbar.l.s-1

Pressure Regulation – Automatic with no need of Foot Pedal or Vacuum Pump

A human machine interface (HMI) shall be provided to display the Glove Pressure,Oxygen level, moisture etc. in English Language and also it shall be used to the other functions such as Regeneration, Auto Flush Mode, Set points for Alarm etc

Operation in Over Pressure only.

Filters – Two HEPA 13 Filters shall be provided at the Inlet and outlet port of Glove box

Front window front panel- Front Panel should be made up of Mineral Laminated Glass of 13.5 mm thickness and sealing shall be done using O ring and without use of silicon. It shall be mounted at 10deg Inclination and which is easily mountable and demountable

Power Supply inside the glove box – One Number of 220-230V electrical feed through for connecting 5A and 16A Load

Lighting – Appropriate LED light shall be provided on the Roof part to illuminate the Inside Glovebox Area and with easy maintenance Blanked Feedthrough- Minimum 4 blanked leak tight feedthrough mounted on the back wall

Glove port – 03 numbers of glove port having standard diameter of 220mm shall be provided on the front panel with the Glove Ring material of PP

Gloves– 03 numbers of ambidextrous Butyl gloves of 0.4mm thickness with required Glove O Rings is provided

Height Adjustable Shelves of Qty 03 nos shall be provided on the back wall of the system.

All piping must be in stainless steel (US304L).

Safety valves –Necessary over pressure relief valve shall be provided along with the system for ensuring the safety and working comfort even during Electrical Failure

Stand – Glove box shall be supplied with a Stainless-steel stand or supporting Height adjustable frame having locking and leveling casters & Dampener made up of corrosion resistant stainless steel Automatic and adjustable Vacuum Chamber Cycles

Power Supply to Glovebox: 220-230 V AC (single Phase, 50 Hz) One Gas Collector

One Glove Port cover for Glove changing One security valve Hepa (the) 5m3/h filter

Main antechamber

Type & Dimension – Cylindrical, Diameter -400 mm, Length 600 mm Material of construction- Stainless Steel 304L grade

Two ALUMINIUM doors having external lifting mechanism for easy maintenance.

Evacuation and Refilling – Evacuating and flushing with inert gas using 03 way control Valve

Leak Rate/ Tightness:-5 mbar.l.s-1

Door Closing & opening mechanism– Easy opening with Gas Cylinders and Easy maintenance

Tray – Sliding Stainless Steel Tray shall be provided inside Main antechamber

Vacuum gauge- Stainless Steel vacuum gauge

Mini antechamber

Type & Dimension – Cylindrical, Diameter -150 mm, Length 400 mm with Hinged Door

Material of construction- Stainless Steel 304L grade

Tray – Sliding and removal Stainless steel Tray shall be provided Leak Rate/ Tightness:-5 mbar.l.s-1

Vacuum Gauge – Stainless Steel vacuum gauge

Gas purification system

Gas purification system –Single column PLC controlled closed loop recirculating Gas Purification system using copper catalyst to remove oxygen and molecular sieve to remove moisture producing less than 1 PPM oxygen and less than 1 PPM H2O environment inside the glove box.

Controlling – Through PLC with touch screen controller Attainable Purification limit –

Purification Capacity – O2 – 30 L & H2O – 1000 g

Regeneration-Automatic regeneration process through PLC using mixture of gases containing N2 or Ar and hydrogen.

Data Recording – The unit has capability to record up to two months’ history of oxygen,moisture and pressure

Vacuum Pump – Dual stage vacuum pump not less than 12m3/h. The vacuum pump is only used to perform antechamber cycles and Shall not be used for pressure regulation of the Glove Box.

Gas purification system has been compactly integrated with glove box.

Regeneration Process

Automatic process, Inlet and outlet regeneration gas through electro valves (solenoid valves) (ENERGY SAVING mode)

Heating of reactor: Integrated temperature regulation controlled through automatic and temperature cut out.

Blower

Recirculation blower, brushless motor type mounted inside a stainless-steel housing,with minimal flow 80m3/h.

H2O analyzer

H2O Sensor type – Ceramic Sensor

Measuring scale: -100 to 20deg C DP and 1000ppm Precision: +/-2 °C DP

7 points calibration certificates (NPL & NIST)

3-wire, type 4 to 20 mA integrated analogic microprocessor Touch screen display

Measuring unit – In °C DP or ppm Resolution: 1 ppm or better

Oxygen analyzer

based with Touch Screen Display which can show the measuring unit in terms of ppm or % and also with Sensor Lifetime Indication, helpful for the calibrating on Field.

Measuring scale: In ppm or % Measuring range: 0-1000 ppm Sensor lifetime indication Resolution: 1 ppm or better

Precision: +/- 1 ppm of the 0-10ppm scale In Lab Air Calibration should be possible.

Solvent removal system

An external solvent removal system with 7.5 kg of solvent absorbing material such as Activated Charcoal for removing solvent vapour from the glove box environment.

Energy Saving Mode

No water chiller needed

No Heat Exchanger Needed

Vacuum Pump exclusively used for Vacuum Cycles. Not for any other functions.

One pressure safety release valve with HEPA filter for automatic mechanical discharge of exceeded gases in the glove box (ENERGY SAVING mode) allowing full automatic pressure adjustment with no need for foot pedal, most reactive pressure adjustment,increased comfort in handlings, excess gas discharge possible even in case of power break.

Low noise level 49 dB(A) under purification and pressure regulation. Required ensuring low power consumption features (max power consumption around 500W, in Energy saving mode around 40W, i.e. around 90% energy saving).

On-site installation and training

- Includes systemstart-up

2-Day operation and maintenance training course

Shipping Terms

FOB destination (no VAT/TAX Includ)

3 Years limited manufacturer warranty

Free technical support

2 AC electrical Plug (115 VAC, 15 A)

Provides electrical receptacles for connecting instruments and equipment inside the glove box

Includes an electrical cord and plug, which may be plugged into the glove box’s interior duplex receptacle

4 receptacles, 115v, rated for 15 amps

For use with Protector or Precise series of gloveboxes

Shock absorber coupling

A marble slab is built into the glove box, which is connected to the outside marble through six shock absorber coupling.

PS: this glove box is a custom glove box, please order 3 months in advance, thanks.