Description:

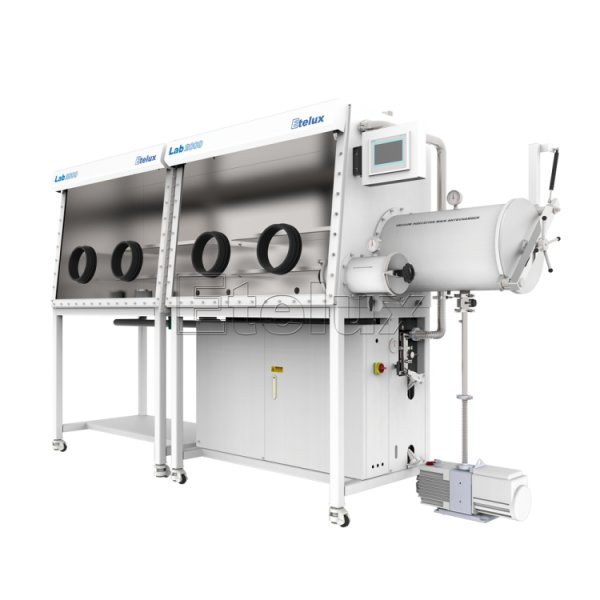

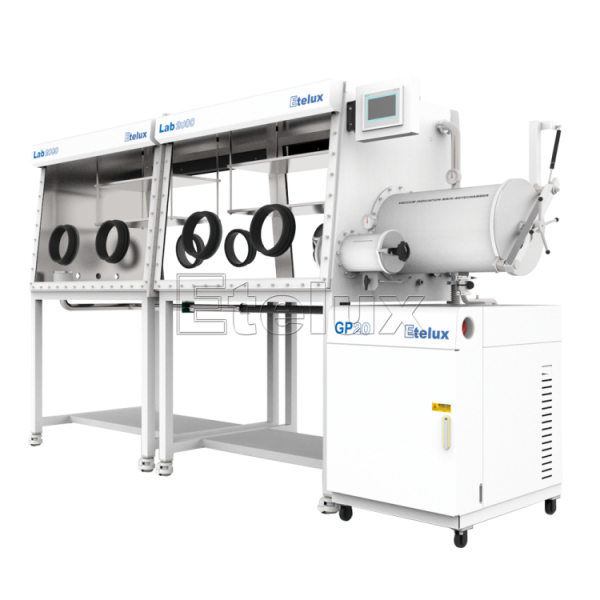

The integrated Sodium-sulfur Energy Storage Battery consists of a vacuum tunnel drying furnace, a pretreatment glove box, a liquid injection glove box, a feeding system, a fully automatic liquid injection machine, a weighing system, a battery cap welding system, a pull-down sealing system, and a feeding system. The production of batteries from drying to sealed batteries is completed in a glove box with ultra-low H2O & O2 content.

Production line advantages:

The upper and lower process chambers in the entire production process are seamlessly connected, and the entire production process realizes anhydrous oxygen transfer and transportation.

Vacuum tunnel drying system professionally completes a single function in each process to achieve a constant high vacuum, low dew point, and high temperature uniformity drying environment, which greatly improves the performance parameters of the product, while guaranteeing single batch and multi-batch products Consistency. It greatly improves the technical parameters such as battery cycle life.

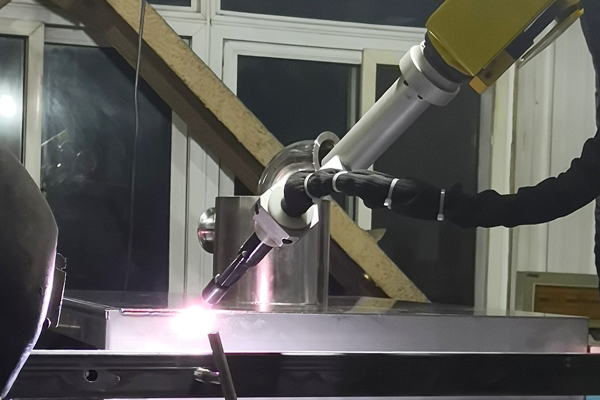

The entire process is fully automated, greatly improving the efficiency of production. The entire liquid injection system adopts advanced integrated pressure detection and leak detection, and has the function of automatically screening for unqualified products. The liquid injection method is followed by a vacuum and a static method of alternating pressure, which greatly improves the product qualification rate. The cap adopts double-layer two-layer symmetrical welding, which has high welding efficiency.

Good consistency.

Pull-down sealing equipment adopts reasonable seal ring compression to ensure good sealing performance.

Reviews

There are no reviews yet.