Product description

GWSP series oil-free scroll vacuum pump is used for vacuuming dry and clean gas. It cannot be used with substances that are harmful to the human body, flammable, explosive, corrosive gases, or contain chemicals, solvents, or substances that can generate powders. The inlet air temperature cannot exceed 50°C. If it exceeds this temperature, a cooling device must be installed on the inlet pipe to keep the inlet air temperature below 50°C.

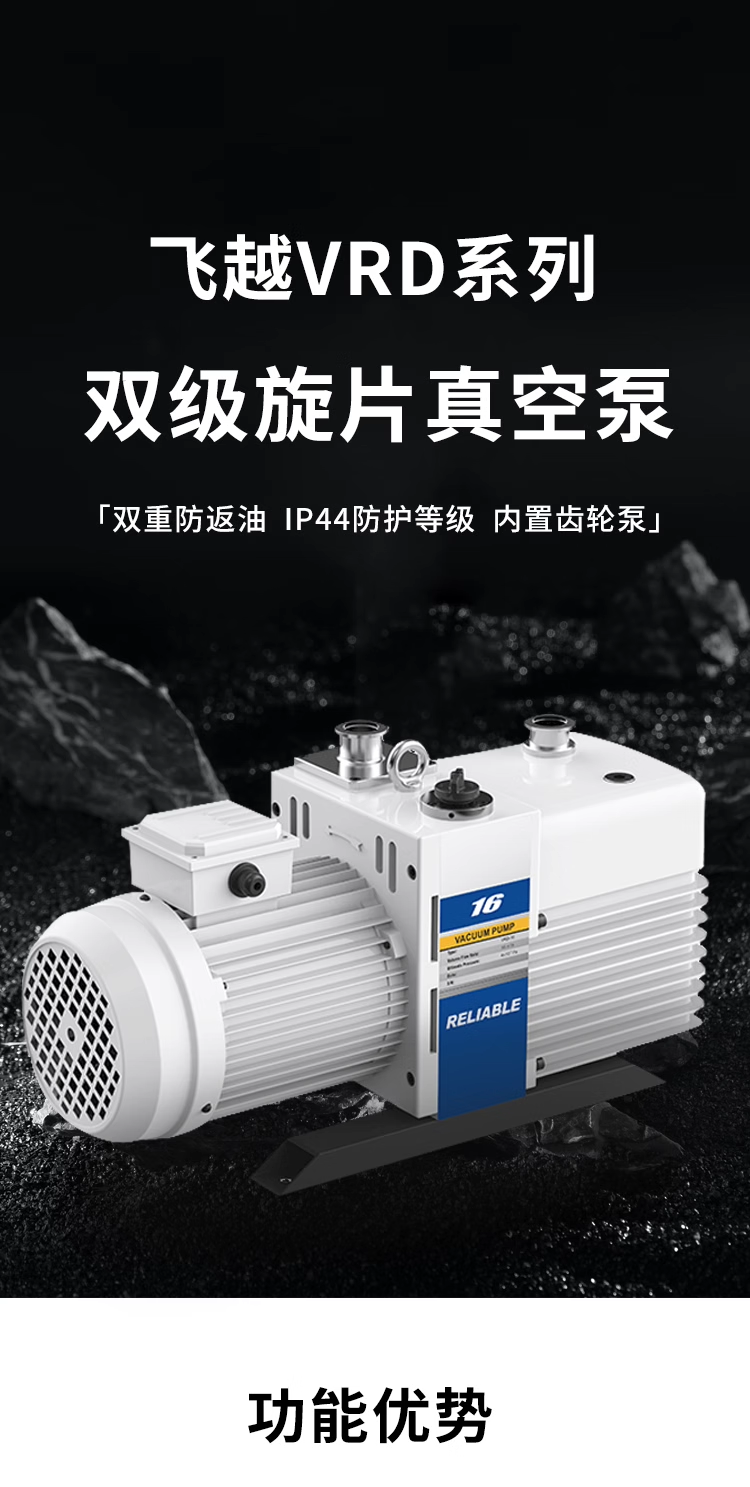

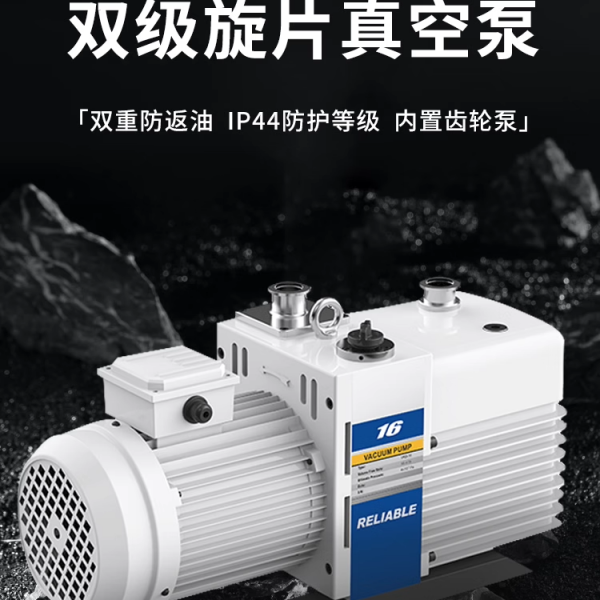

Basic principles of Feiyue vacuum pump

Feiyue vacuum pump is an efficient and reliable vacuum suction equipment widely used in various industries. Its basic working principle is to drive the impeller to rotate through the motor, forming a low-pressure area in the pump, and sucking gas or steam from the high-pressure area to the low-pressure area, thereby achieving the effect of discharging gas or generating a vacuum. The flyover vacuum pump has many advantages, such as it can work under high vacuum, has high efficiency and long life, in addition, it can handle various gases, including corrosive gases and high-temperature gases. However, flyby vacuum pumps also have some disadvantages. For example, it requires periodic maintenance and cleaning to ensure it operates properly. Additionally, it requires a certain energy supply to keep it running. Overall, the flyover vacuum pump is a very important piece of equipment that has a wide range of applications in many fields. While it has some disadvantages, its advantages far outweigh its disadvantages, making it an integral part of many industries.

How to use Feiyue vacuum pump

1. Start and shut down the pump: First press the power button to start the pump, then adjust the valves at the air outlet and air inlet to achieve the required pressure. After use, first close the air inlet and then turn off the power button.

2. Maintain and clean equipment: Clean the filter screen and filter element of the pump regularly to prevent the air inlet from being blocked by dust and dirt. At the same time, avoid contamination of the pump by excessive pressure or overheated air during use, which will affect the performance of the equipment.

3. Solutions to common problems:

(1) The pump cannot be started: Check whether the power supply is connected properly to ensure circuit safety.

(2) Excessive noise: Check whether the installation position of the pump is stable, and check whether the filter element is clean. (3) No air flow at the exhaust port: Check whether the air inlet is blocked, and check whether the inlet and outlet valves of the pump are closed.

Feature

Wide pumping speed range, from 1L/s to 16L/s

·Ultimate vacuum reaches 1 Pa

Applicable to global power supply, 110/220/380/460V

50/60Hz

·No oil at all, no oil return or oil injection

·Able to start frequently between atmospheric pressure and vacuum

·Low vibration, low noise, low energy consumption。

Size

| model | A | B | C | D | E | G | H | I | J | K | L | DN |

| VRD-4 | 440 | 144 | 217 | 210 | 110 | 95 | 143.5 | 45 | 45 | 34 | / | KF16/25 |

| VRD-8 | 440 | 144 | 217 | 210 | 110 | 95 | 143.5 | 45 | A5 | 34 | / | KF16/25 |

| VRD-16 | 530 | 188 | 272 | 320 | 148 | 160 | 165 | 69 | 59 | 38 | 295 | KF25 |

| VRD-24 | 567 | 188 | 272 | 320 | 148 | 160 | 185 | 82 | 59 | 47 | 295 | KF25/40 |

| VRD-30 | 567 | 188 | 272 | 320 | 148 | 160 | 185 | 82 | 59 | 47 | 295 | KF25/40 |

| VRD-48 | 730 | 234 | 358 | 396 | 190 | 200 | 223 | 157 | 69 | 55 | 390 | KF40 |

| VRD-65 | 730 | 234 | 358 | 396 | 190 | 200 | 223 | 157 | 69 | 55 | 390 | KF40 |

| VRD-90 | 30 | 234 | 358 | 396 | 190 | 200 | 223 | 157 | 69 | 55 | 390 | KF40 |

Technical Parameters

| project | VRD-4 | VRD-6 | VRD-16 | VRD-24 | ||

| Pumping speed | 50Hz | m3/h

(L/s) |

4(1.1) | 8(2.2) | 16(4.4) | 24(6.6) |

| 60Hz | 4.8(1.3) | 9.6(2.6) | 19.2(5.2)) | 28.8(7.9) | ||

| The ultimate partial pressure turns off the gas ballast | Pa | 5×10-2 | 5×10-2 | 4×10-2 | 4×10-2 | |

| Ultimate full pressure, one-off gas ballast | Pa | 5×10-1 | 5×10-1 | 4×10-1 | 4×10-1 | |

| The gas ballast is turned on as soon as the maximum full pressure is reached | Pa | 10 | 10 | 8×10-1 | 8×10-1 | |

| power supply | single/three phase | single/three phase | single/three phase | single/three phase | ||

| power | kw | 0.4/0.37 | 0.4/0.37 | 0.75/0.55 | 0.75/0.55 | |

| Protection level | IP44 | IP44 | IP44 | IP44 | ||

| Intake and exhaust interface | KF16/25 | KF16/25 | KF25 | KF25 | ||

| Oil volume | L | 0.6-1.0 | 0.6-1.0 | 0.9~1.5 | 0.9~1.5 | |

| Motor speed (50/60Hz) | RPM | 1440/1720 | 1440/1720 | 1440/1720 | 1440/1720 | |

| Working temperature | degrees celsius | 10-40 | 10-40 | 10-40 | 10-40 | |

| Noise(50Hz) | Db | <=52 | <=52 | ≤58 | ≤58 | |

| weight | kg | 19 | 21 | 30 | 35 | |

| Size(L*W*H) | mm | 440x144x217 | 440x144x217 | 530x188x272 | 530x188x272 | |

| project | VRD-30 | VRD-48 | VRD-65 | VRD-90 | ||

| Pumping speed | 50Hz | m3/h

(L/s) |

30(8.3) | 48(13.3) | 65(18) | 85(23.6) |

| 60Hz | 36(9.9) | 57.6(16) | 78(21.6) | 102(28.3) | ||

| The ultimate partial pressure turns off the gas ballast | Pa | 4×10-2 | 4×10-2 | 4×10-2 | 4×10-2 | |

| Ultimate full pressure, one-off gas ballast | Pa | 4×10-1 | 4×10-1 | 4×10-1 | 4×10-1 | |

| The gas ballast is turned on as soon as the maximum full pressure is reached | Pa | 8×10-1 | 1.5 | 1.5 | 1.5 | |

| power supply | single/three phase | three phase | three phase | three phase | ||

| power | kw | 1.1 | 1.5 | 2.2 | 3 | |

| Protection level | IP44 | IP44 | IP44 | IP44 | ||

| Intake and exhaust interface | KF25/40 | KF40 | KF40 | KF40 | ||

| Oil volume | L | 1.3-2.0 | 3.3~4.5 | 3.3~4.5 | 3.3~4.5 | |

| Motor speed (50/60Hz) | RPM | 1440/1720 | 1440/1720 | 1440/1720 | 1440/1720 | |

| Working temperature | degrees celsius | 10-40 | 10-40 | 10-40 | 10-40 | |

| Noise(50Hz) | Db | ≤58 | ≤62 | ≤62 | ≤65 | |

| weight | kg | 43 | 62 | 65 | 65 | |

| Size(L*W*H) | mm | 567x188x272 | 730x234x358 | 730x234x358 | 730x234x358 | |