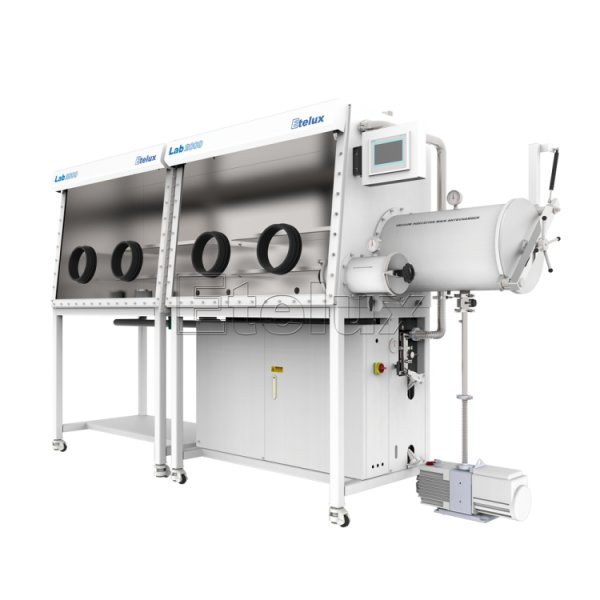

Laser welding glove box, military glove box laser welding machine

General device description:

High-quality standardized laser welding glove box system to meet the needs of laser welding applications in specific inert atmospheres.

Function and usage introduction:

The laser package welding system can weld various metal alloys such as stainless steel, alloy, aluminum, copper, etc. in a H2O-free and O2-free environment. (Full GJB548B-2005 leak detection index) can be used for microwave devices, RF packages, T / R components, pacemakers, sensors, lithium batteries, other micro-welding, etc.

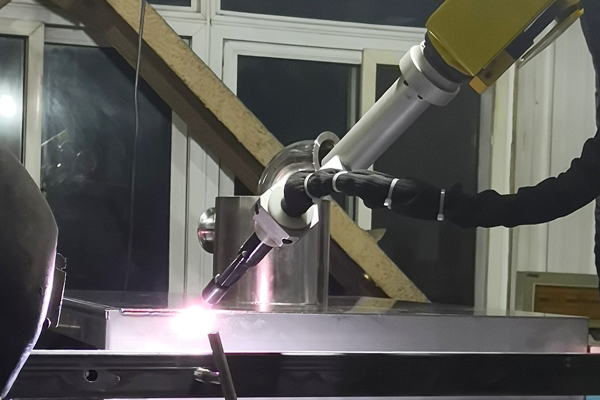

Working principle:

- Use a laser beam to fuse the metal to be welded above the melting temperature to form a weld.

- The basic structure of laser welding machine includes laser, welding head, cooling system, numerical control device and operating software.

- Laser sealing welding also requires welding in a special atmosphere or vacuum environment.

Product advantages:

- Floor structure. Compact structure and good compressive strength.

- Major equipments such as lasers and motion platforms adopt internationally renowned brands to ensure equipment quality and equipment operation stability.

- PC intelligent control, CCD image positioning, accurate positioning and tracking welding, guaranteeing welding quality.

- The laser welding pulse waveform is programmable, the control system turns at a uniform speed, and the welding seam is uniform.

- The energy of laser welding can be controlled to rise and fall slowly.

The laser system:

1.Highly reliable and humanized glove box design

2.Vacuum oven — precise temperature control

3.Dust removal system — clean and closed welding dust removal system

4.Purification system — Renewable highly purified system

5.Positioning system — Fully automatic seam tracking positioning system

6.Gate control system — Automatic lifting control of inner box door

7.Self-locking system — internal and external door self-locking system

Reviews

There are no reviews yet.