| Basic Configuration | ||

| Description | Material: stainless steel 1.4301 (SUS type 304)

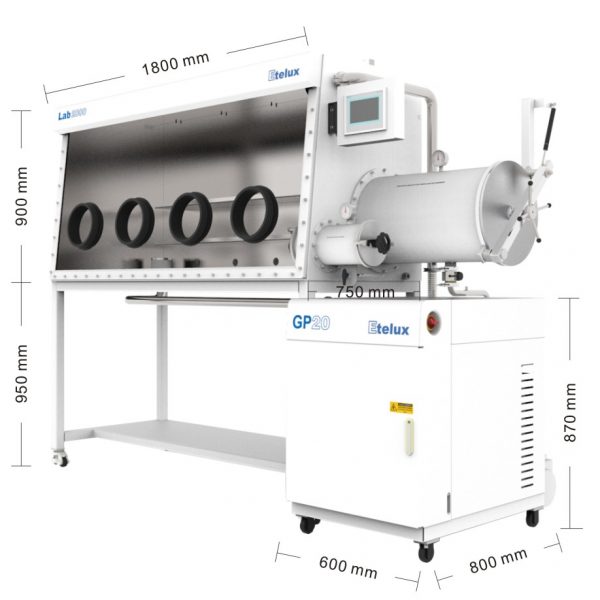

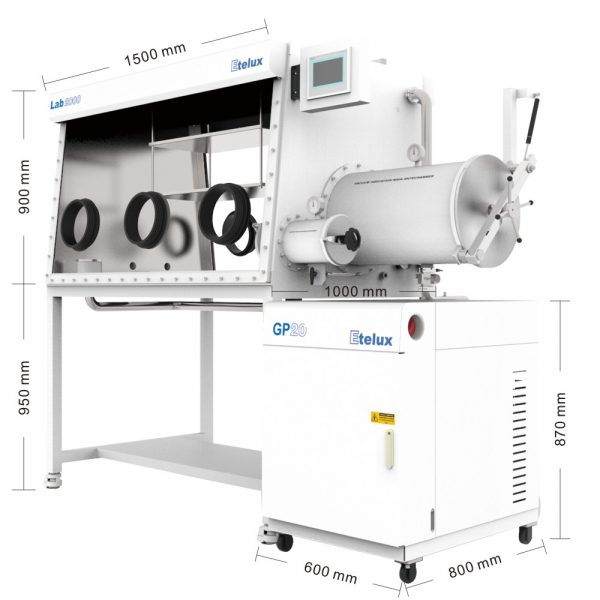

49.9 “(1267.5 mm) wide x 32.9” (835.7 mm) deep x 76.6 “(1945.9 mm) high |

|

| Vacuum gauge | 0 to -30″ Hg | |

| Inert gas line | All 316L stainless steel | |

| Pressure gauge | 0-100 psi | |

| Main system pressure isolation | Two-way 1/4 “stainless steel ball valve | |

| Main system pressure release | 70 psi | |

| Electrical ground | Telescopic ground wire for solvent ground | |

| Caster | Movable casters | |

| Leak rate | Leak detection is carried out in accordance with the oxygen method and pressure change method in ISO 10648-2: 1994 / EJ / T 1096-1999 “Sealed Boxes-Part 2: Sealing Classification and Related Inspection Methods” Sealed according to the first level | |

| Valve configuration | ||

| Valve racket | 304 stainless steel road | |

| Drain / fill / dispense valve | Five-way valve, easy to use and safe, eliminates the possibility of dispensing solvents into the vacuum pump | |

| Solvent metering valve | Stainless steel needle valve | |

| Collection bottle inert gas replenishment | Separate low pressure regulator, 7 psi pressure relief valve | |

| Collection flask connection fitting | Stainless steel 19/24/40 is standard, other sizes are available | |

| Horizontal clamping column for collection bottles | Height adjustable | |

| Leak rate | Leak detection is carried out in accordance with the oxygen method and pressure change method in ISO 10648-2: 1994 / EJ / T 1096-1999 “Sealed Boxes-Part 2: Sealing Classification and Related Inspection Methods” According to Class 1 tightness | |

| Double purification column design | ||

| A Pillar | Matrial | Stainless steel type 304 (1.4301), thickness 2 mm |

| Size | 4 “(101mm) outer diameter x 25” (635mm) L, internal volume = 1 gallon (4L) | |

| Inlet / outlet valve | 3-way 1/4 “stainless steel, allowing easy troubleshooting | |

| Drying capacity | Common 800L based on HPLC grade solvents | |

| B Pillar | Matrial | Stainless steel type 304 (1.4301), thickness 2 mm |

| Size | 4 “(101mm) outer diameter x 25” (635mm) L, internal volume = 1 gallon (4L) | |

| Inlet / outlet valve | 3-way 1/4 “stainless steel, allowing easy troubleshooting | |

| Drying capacity | Common 800L based on HPLC grade solvents | |

| Connect liquid tray | ||

| Description | 304 stainless steel, adjustable height. | |

| Solvent bucket | ||

| Description | 304 stainless steel 20L volume

2 “Quick-Release Flange for Solution Replenishment Color code fast switching to distinguish solvents Regulator with quick disconnect for inert gas push |

|

| Flammable explosion-proof storage cabinet | ||

| Description | Integrated in the lower part of the system frame

Holds up to 5 × 20L solvent buckets |

|

| Vacuum pump | ||

| Description | Dry pump or diaphragm pump for maximum solvent usability

Pumping speed 20L / min Extreme vacuum 6Torr |

|

| Particle filter | ||

| Description | Stainless steel, 7 microns | |

| 选配设备 | ||

| Glove Box Connection Kit | Can be connected and integrated in the cabinet

Chamber 304 stainless steel Including fittings and valves |

|

| Heating regeneration | Regenerative heating system, temperature is 200 ℃, temperature control ± 1 ℃ | |

| Other instructions | ||

| Certified product | ISO9001 Certification, CE certification, UL certification | |

| Warranty | One year warranty and lifetime maintenance | |

| Application considerations | Please refer to the danger, warning, caution, etc. | |

Reviews

There are no reviews yet.